INTRODUCTION:-

Jute is a long, soft, shiny vegetable fiber that can be spun into coarse, strong threads. It is produced from plants in the genus Corchorus, family Tiliaceae. It falls into the bast fibre category (fibre collected from bast or skin of the plant) along with kenaf, industrial hemp, flax (linen), ramie, etc. The industrial term for jute fibre is raw jute. The fibres are off-white to brown, and 1–4 meters (3–12 feet) long.

CULTIVATION:-

Jute needs a plain alluvial soil and standing water. The suitable climate for growing jute (warm and wet climate) is offered by the monsoon climate during the monsoon season. Temperatures ranging 20˚ C to 40˚ C and relative humidity of 70%–80% are favourable for successful cultivation. Jute requries 5–8 cm of rainfall weekly with extra needed during the sowing period.

The jute fibre comes from the stem and ribbon (outer skin) of the jute plant. The fibres are first extracted by retting. The retting process consists of bundling jute stems together and immersing them in low, running water.

There are two types of retting: stem and ribbon. After the retting process, stripping begins. Women and children usually do this job. In the stripping process, non-fibrous matter is scraped off, then the workers dig in and grab the fibres from within the jute stem.

There are two types of retting: stem and ribbon. After the retting process, stripping begins. Women and children usually do this job. In the stripping process, non-fibrous matter is scraped off, then the workers dig in and grab the fibres from within the jute stem.

CHEMICAL COMPOSITION:-

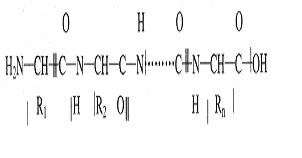

Jute fibres are composed primarily of the plant materials cellulose (major component of plant fibre) and lignin (major components wood fibre). It is thus a ligno-cellulosic fibre that is partially a textile fibre and partially wood.

CHEMICAL PROPERTIES:-

۞ EFECT OF ACIDS:-

Concentrated mineral acids dissolve jute and dilute mineral acids rot it quickly.

CHEMICAL PROPERTIES:-

۞ EFECT OF ACIDS:-

Concentrated mineral acids dissolve jute and dilute mineral acids rot it quickly.

۞ EFFECT OF SALT WATER:- Jute is especially weak in salt water.

۞ EFFECT OF BLEACHES:-

It is difficult to bleach jute and color it.

It is difficult to bleach jute and color it.

PHYSICAL PROPERTIES:-

۞ TENAITY:-

It has high tensile strength, low extensibility, and ensures better breathability of fabrics. Therefore, jute is very suitable in agricultural commodity bulk packaging.

۞ TENAITY:-

It has high tensile strength, low extensibility, and ensures better breathability of fabrics. Therefore, jute is very suitable in agricultural commodity bulk packaging.

۞ THERMAL CONDUCTIVITY:- It has a low thermal conductivity and manufacture with no skin irritations.

۞ ELASTIC PLASTIC NATURE:- It is lack of strenght and therefore it is very difficult to bleach it, to give maximum whitness.

۞ AGROSCOPIC NATURE:- Jute has a moderate moisture regain.

USES:-

1. Jute is used chiefly to make cloth for wrapping bales of raw cotton, and to make sacks and coarse cloth.2. The fibres are used alone or blended with other types of fibres to make twine and rope.3. Jute can be used to create a number of fabrics such as Hessian cloth, sacking, scrim, carpet backing cloth (CBC), and canvas.4. It is a strong, durable, color and light-fast fibre.5. Jute fibres are also being used to make pulp and paper.

1. Jute is used chiefly to make cloth for wrapping bales of raw cotton, and to make sacks and coarse cloth.2. The fibres are used alone or blended with other types of fibres to make twine and rope.3. Jute can be used to create a number of fabrics such as Hessian cloth, sacking, scrim, carpet backing cloth (CBC), and canvas.4. It is a strong, durable, color and light-fast fibre.5. Jute fibres are also being used to make pulp and paper.